What is Cryostorage?

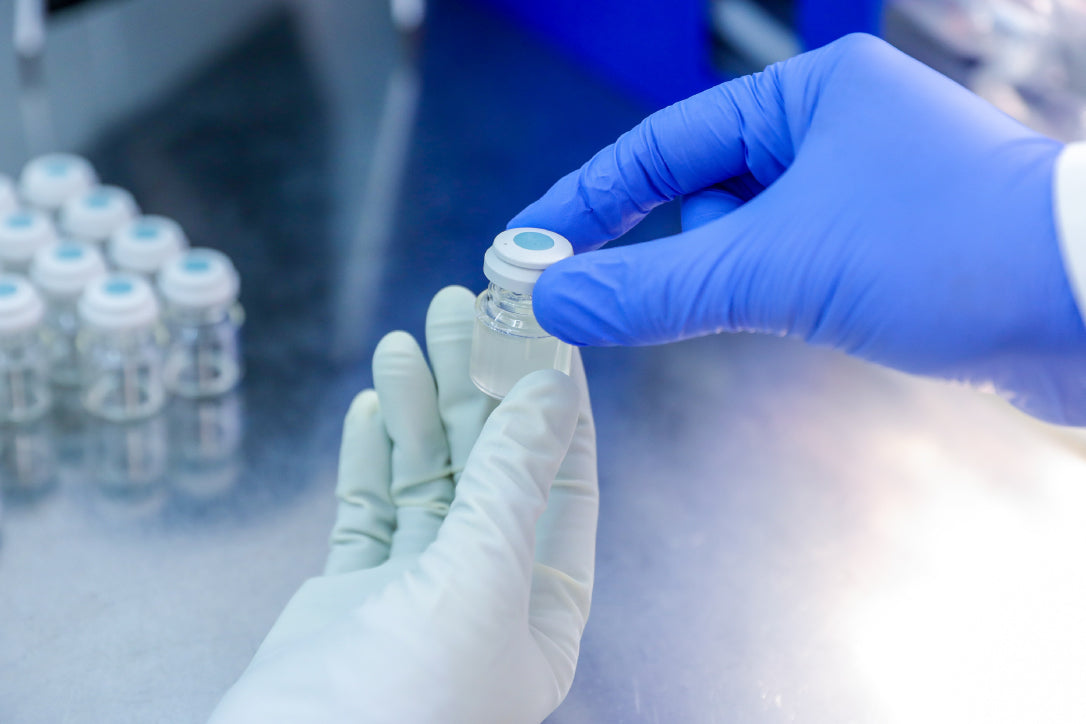

Cryostorage involves the storage of materials at extremely low temperatures, typically at -150°C or colder. These conditions are crucial for preserving the quality of biological samples, such as blood, tissue, and DNA, as well as other materials that are sensitive to temperature changes.

The Challenges of Traditional Cryostorage

Traditional cryostorage systems have long relied on manual checks and mechanical temperature logs to ensure the right storage conditions. However, these methods have limitations:Inaccuracy: Human error in logging data or misreading instruments can result in incorrect information.

Limited Data Points: Traditional methods usually offer only periodic checks, leaving gaps where problems could go undetected.

No Real-Time Alerts: Mechanical systems can't send real-time alerts in case of temperature fluctuations, leaving samples at risk.

How IoT Can Help

Continuous Monitoring

IoT devices can provide continuous, real-time monitoring of cryostorage conditions. Sensors can be placed inside cryogenic storage units to monitor temperature, humidity, and even the integrity of the container seal.Data Accuracy and Analytics

IoT-enabled cryostorage systems can record data with higher accuracy and consistency. The collected data can be analysed to observe long-term trends, predict potential issues, and improve storage conditions.Real-Time Alerts

In the case of any abnormalities like a temperature rise or seal breach, the smart systems can immediately send real-time alerts to concerned personnel, thereby minimising the risk of spoilage.Remote Access

With IoT, it's possible to monitor cryostorage conditions remotely, making it easier to manage multiple storage units across different locations.

Use Cases

Healthcare Industry

IoT-based cryostorage has been instrumental in the healthcare sector for preserving vaccines, especially during mass immunisation drives. With millions of doses requiring stringent temperature control, IoT systems have been critical in averting spoilage and ensuring effective immunisation.Research and Development

In research settings where biological samples are invaluable, IoT has provided researchers with the peace of mind that their specimens are stored under optimal conditions, allowing them to focus more on their research and less on logistics.

"As we navigate the complexities of modern science and healthcare, the synergy between IoT and cryostorage isn't just a luxury—it's a necessity for progress and safety."

Modern Cryostorage

IoT technology is rapidly becoming an integral part of modern cryostorage solutions. With advantages like real-time monitoring, high data accuracy, and instant alerts, IoT is setting new standards in ensuring the safety and efficacy of cryogenically stored materials. As IoT technologies continue to evolve, we can expect even more robust and reliable cryostorage systems in the future.