In the pharmaceutical industry, the efficacy and safety of medications can be compromised by even slight variations in temperature, humidity, or other environmental factors. Pharmaceutical cold chain monitoring is a process that maintains specific temperature conditions throughout the entire temperature-controlled journey of pharmaceutical products. The primary goal is to ensure that the pharmaceutical products reaching patients are potent and safe. This article explores why environmental monitoring is so vital in ensuring the quality of pharmaceutical products during transportation and storage.

The Stakes Are High

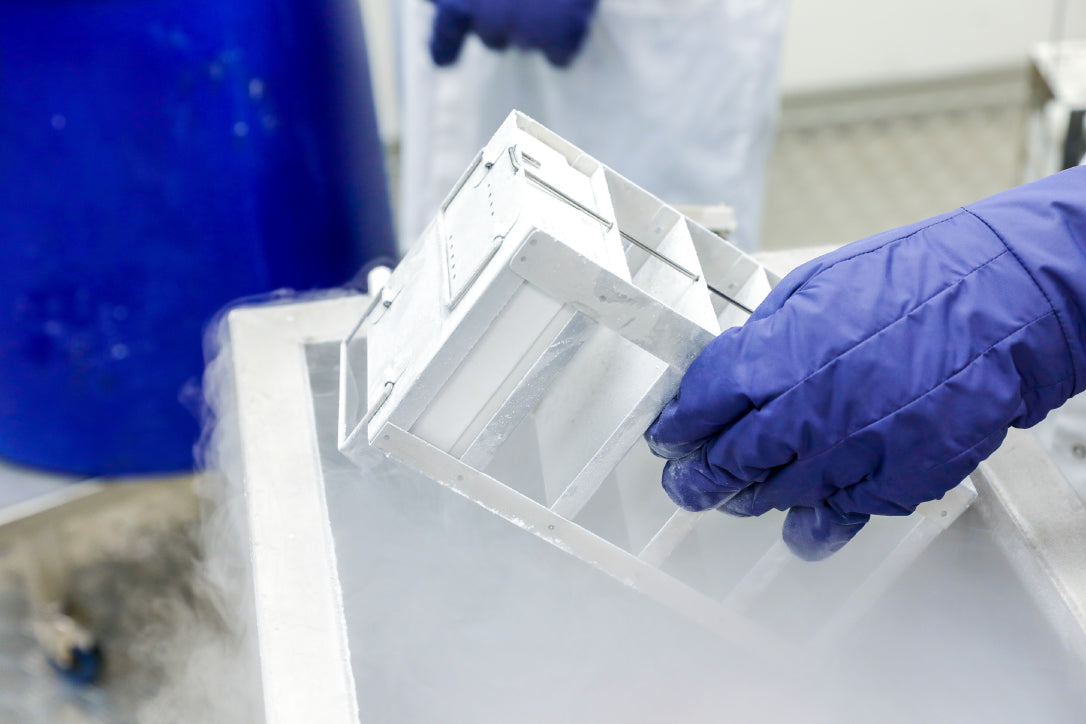

Pharmaceuticals often require specific, controlled environmental conditions to maintain their integrity. Vaccines, for instance, may lose their effectiveness if exposed to temperature fluctuations. Even a short exposure to improper conditions can render these critical medical supplies useless, potentially risking lives.

Regulatory Compliance and Quality Assurance

Governments and industry bodies often set stringent standards for the storage and transportation of pharmaceuticals. Consistent, reliable monitoring ensures that these products are compliant with regulatory bodies like SAHPRA, avoiding costly fines and, more importantly, ensuring product integrity and ultimately, patient safety.

GxP Good Practices

GxP refers to the guidelines and regulations formulated and enforced by various national and international agencies like the FDA and WHO. These guidelines ensure that products, from manufacturing to processes, are safe to use. GxP practices comprise five elements commonly referred to as 5Ps: People, Procedures, Products, Premises and equipment, and Processes.

"In pharmaceuticals, environmental monitoring is more than a compliance task—it's a public health necessity. Real-time data ensures both product integrity and patient safety."

Impact on Product Quality and Patient Safety

Deviations from a product’s recommended temperature range can compromise its chemical composition, stability, and efficacy, thus impacting patient safety. Examples of temperature-sensitive medications include Insulin, COVID-19 Vaccine, and Oncology Treatments. So keeping these products within the specified temperature range is paramount.

Technology and Tools

Advanced technologies like USB dataloggers and real-time cellular monitoring devices are crucial for collecting temperature data at a product- or shipment-level throughout the supply chain. Other tools include Passive Dataloggers, Real-Time Temperature Monitors, and Stationary Temperature Monitoring.

Importance of Real-Time Monitoring

Real-time environmental monitoring systems can provide immediate alerts for any deviation from the set conditions. These devices can track temperature, humidity, and other environmental factors to ensure the products are stored and transported under ideal conditions. Immediate notifications mean immediate action, reducing the risk of product loss or inefficacy, solutions like Nvirosense, our Cloud-Based Platform can provide live insights into a product’s temperature, humidity, location, and more allowing for proactive intervention.

Data-Driven Decision-Making

Having access to live and historic environmental monitoring data not only helps in real-time but also contributes to predictive analytics. By analysing the data collected, companies can identify potential weak spots in their cold chain logistics and address them proactively, before a crisis occurs.

Better Monitoring, Better Earth

Far from being merely a regulatory mandate, environmental monitoring plays an essential role in safeguarding the quality and safety of pharmaceutical items. Leveraging advanced monitoring technologies and software tools can markedly improve the management of the cold chain, thereby ensuring that products remain intact and safe for consumers.

Additionally, effective environmental monitoring has a positive impact on sustainability. By optimising the use of cooling systems and planning transportation routes efficiently, we can minimise the environmental impact of the cold chain, saving money and reducing our footprint.