Why Industry Edge Controllers?

As the implementation of smart manufacturing and the Industrial Internet of Things continues to advance, the need for edge computing and cloud storage of on-site data has become essential for many contemporary factories. The limited capabilities of traditional PLCs, which are primarily used for small-scale device control, are no longer sufficient for these modern manufacturing environments. As a result, factories are now in need of controllers that possess enhanced communication abilities, are capable of handling large amounts of data, can multitask and collaborate effectively, and have the ability to connect to cloud services for remote processing and real-time control.

At the same time, with the expansion of production scale, new demands for cross-equipment, cross-factory, and even cross-country communication, and data analysis are getting more and more important for the factories. This also poses higher challenges to PLC capabilities: the vertical coordination of the entire production line and the entire factory area, and the horizontal coordination of industrial control software, SCADA system. Therefore, Industrial Control + Internet + Intelligence has become a new trend in PLC development.

EUCA Technologies supplier of Seeed Studio, who is also the design partner of Raspberry Pi, has been investing in developing the Raspberry Pi industry devices to satisfy diversified Industrial Internet of Things (IoT/IIoT) needs and has recently launched the Edge Series to meet the different needs of users.

"Factories need controllers with stronger communication, big data processing, multitasking and collaboration, and the ability to connect to the cloud for remote processing and real-time control."

What is the Edge Series?

The Edge Series is a lightweight industrial edge controller series launched by Seeed Studio. It is defined as an OT-IT Bridge in industrial automation scenarios, integrating PLC/PAC, IPC, IIOT gateway, OPC UA Server, and even HMI in the case of the Edgelogix-RPi-1000. The Edgelogix-RPi-1000 and EdgeBox-RPi 200 are powered by Raspberry Pi Computer Module 4 (CM4), and EdgeBox-ESP-100 is powered by ESP.

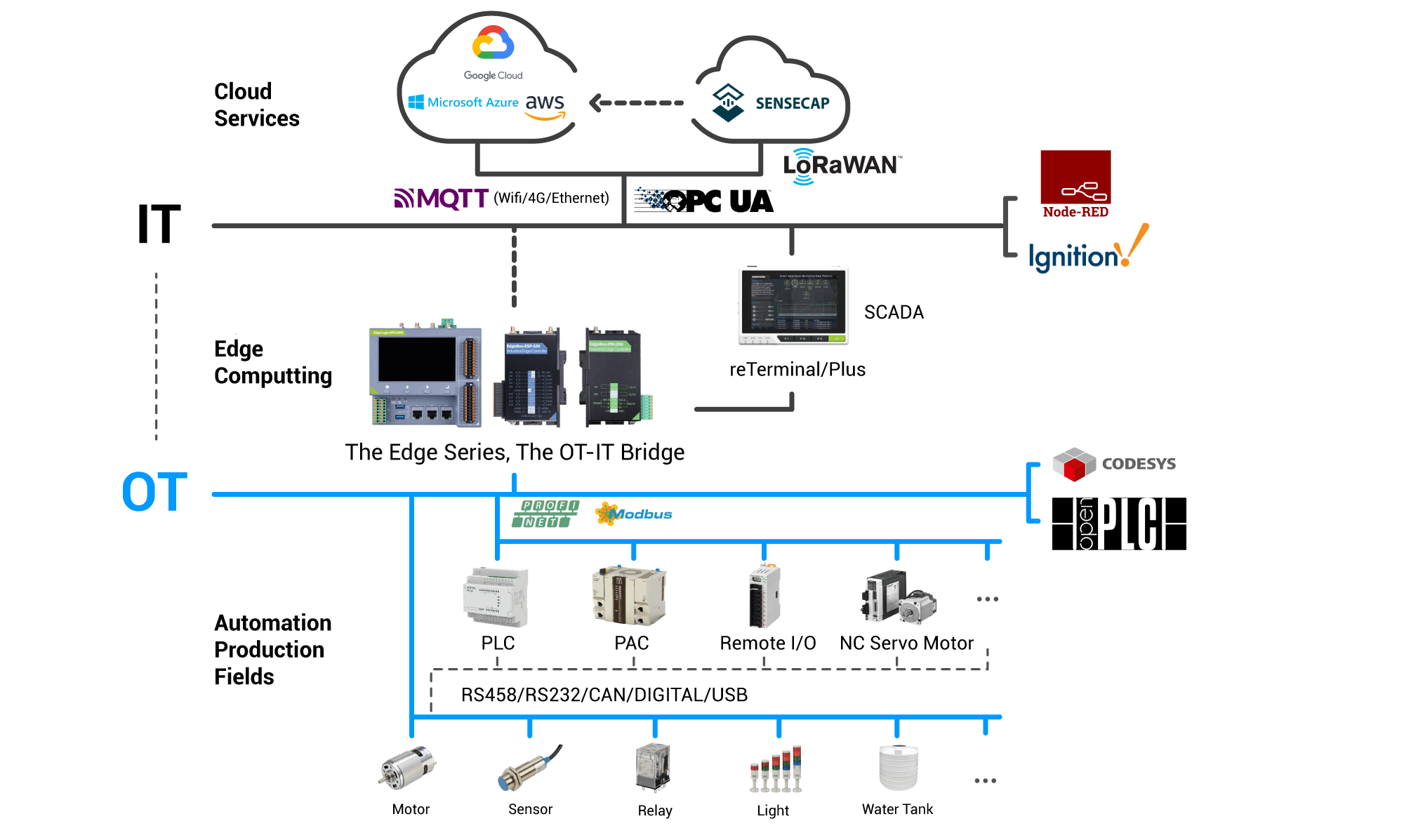

The Edge Series builds the OT (Operational Technology) and IT (Information Technology) communication bridge between traditional controllers, actuators, and cloud services. It plays as the SCADA system together with Embedded Computers, such as the reTerminal/Plus, providing an affordable, available, and also reliable industry automation solution.

How does Edge Series Work?

The Edge Series, designed and manufactured in compliance with industrial standards, makes the seamless connection between OT and IT with multiple industrial fieldbus or protocols, such as RS485/232, CANBUS, Profinet, Modbus, and network transmissions like Ethernet, 4G, LTE, LoRa, WiFi and Bluetooth.

The Edge Series receives field data (sensors, control IO, etc.) and executes multi-threaded data local calculations. This greatly protects data security, improves data processing accuracy, and real-time performance. It constitutes the SCADA system together with the reTerminal/Plus, which functions as the Panel PC. From there, the data can be transmitted to the Cloud for storage, remote management, and control relying on its software and wireless capability.

The whole system (The Edge Series + reTerminal/Plus) serves as the OT-IT bridge in the middle “Edge Computing” layer, connecting the Automation Production Fields and the Cloud service. Here EUCA Technologies and Seeed Studio provides you with the private cloud possibility thanks to SenseCAP.

"The architecture above details the closed-loop control of the whole process from “Connection-Collection-Analysis-Decision-Connection” for an automated factory, and finally improve the overall productivity of the factory."

Customers will benefit from the open-source software ecosystem of the Raspberry Pi, and the cost of using and learning the Edge Series is lower. More people, more engineers, and more factories can use the Edge Series to achieve the desired industrial automation that is needed.

The Edge Series

EdgeLogix-RPi-1000

EdgeLogix-RPI-1000 is a Raspberry Pi-based industrial controller capable of all-in-one application scenarios.

Designed with intensive IO ports and delicate modules mounted on board, it also supports extensive industrial bus protocols (such as the high-speed local bus), and is equipped with cloud service support. Which has extraordinarily increased the ability to manage complex systems and sophisticated machines. Therefore, not only is it the PLC & PAC, but also the IIoT Gateway, Lightweight HMI, OPC UA Server, and Industry PC.

Rich IO Resources- 24 isolated DI, DO along with RS485, RS232, 3*1000M RJ45

- High-speed local BUS extension

- Additional DIO, ADC, and relay expansion modules

- Powered by Raspberry Pi CM4 up to 8GB RAM and 32GB eMMC, supports Debian, Linux, and Ubuntu OS

- Build in 2.4 GHz/ 5.0 GHz WIFI, IEEE 802.11 b/g/n/ac

- Mini-PCIe slot for 4G LTE and LoRaWAN modules.

- IT connectivity of DHCP/DNS, OPC UA, and web server

- IEC 61131-3 with CODESYS, Node-RED, and MQTT.

- AWS, and Azure cloud services

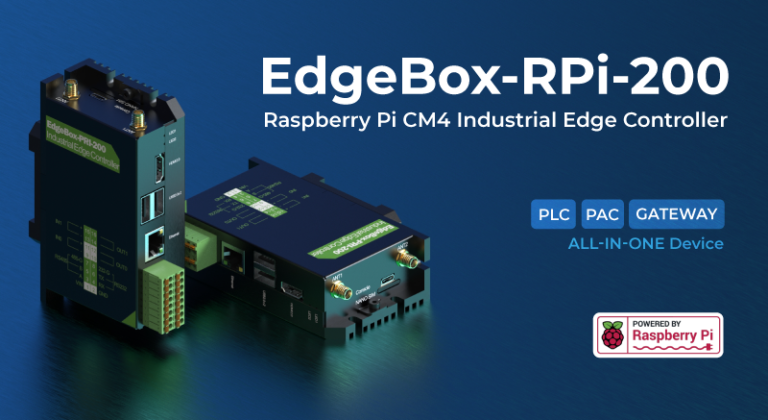

EdgeBox-RPi-200

EdgeBox-RPi-200 series are all-in-one Raspberry Pi-based industrial edge computing controllers, that combine multiple industrial purposes. It is equipped with up to 4GB RAM and 32GB eMMC for various requirements.

Designed as high-scalability and rugged industrial hardware, mounted with rich IO resources, and supported by the great Raspberry Pi industrial software ecosystem, it is an ideal choice for smart automation and Industrial Internet of Things (IIoT) solutions.

EdgeBox-RPi-200 series controllers represent the conceivable alternatives for increasing edge automation and industrial interconnecting control. Being small and compact, they can perform real-time operations and multi-process controlling for multiple industrial purposes, not only the PLC & PAC but also the IIoT Gateway, OPC UA Server, and Industry PC.

Powerful and Flexible Processors- Powered by Raspberry Pi Compute Module 4, running up to 1.5GHz, up to 4GB RAM, and 32GB eMMC.

- 2x isolated DI; 2x isolated DO

- 1x isolated RS485; 1x RS232

- 2x USB2.0 A

- 1x M2 slot support 2242 NVME SSD

- 1x HDMI 2.0 up to 4K@60fps

- RS485/RS232

- TCP IP

- Modbus

- OPC UA

- IEC 61131-3 compliant

- Built-in 2.4G/5G WiFi, BLE 5.0

- Gigabit Ethernet RJ45 Port

- Mini PCIe slot support 4G LTE/LoRaWAN Gateway/Zigbee Module

- Support AWS and Azure Cloud services

- CODESYS

- Node-Red

- MQTT

- OPC UA

- Ignition

EdgeBox-ESP-100

EdgeBox-ESP-100 is an ESP32-based controller designed for lightweight automation solutions. It has rich isolated IO and supports multiple fieldbus, including analog input/output, and thus can effectively act as a remote monitor and controller.

Owing to the on-chip Wi-Fi and BLE, and the pre-installed 4G LTE Cellular module, it can be utilized to establish an industrial gateway, enabling the original PLC to connect to the network or cloud. This compact box also comes with rugged hardware and a reliable electrical design, which help maintain its function in a wide temperature range and provide high surge and short circuit protection.

Features

- Multi-Fieldbus Support: CAN, RS485, Ethernet

- Multi-wireless Capability: On-chip Wifi, BLE connectivity; built-in Cellular 4G LTE module

- Reliable Hardware Design: Rugged, maintenance-reduced structure

- Reliable Electrical Design: High isolation, High surge, and short circuit protection

- IEC 61131-3 compliant programs support (under development)

- Programmable with ESP-IDF

- Quality Guaranteed: 2-year Warranty, RoHS/CE/FCC/UKCA/TELEC certified

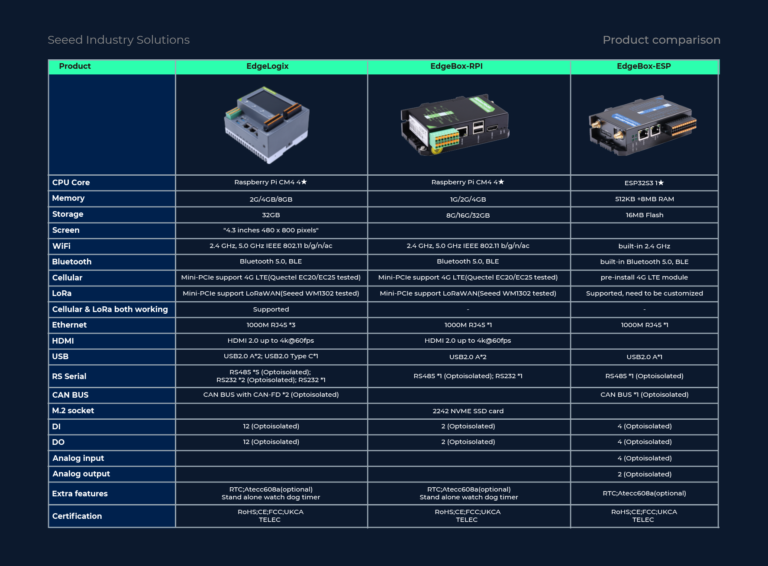

For a detailed specification comparison of the Edge Series devices view the image below or this spreadsheet.

Seeed Studio has been hoping that more factories can achieve digital transformation and realize the connection between IT and OT. We have been trying to make digital transformation and Industry 4.0 no longer just the “privilege” of large factories.

Affordable

- Low purchase cost: Aligned with Seeed Studio, EUCA has always emphasized ensuring lower prices for users through technologies and innovation on the basis of meeting the needs of industrial scenarios

- Low maintenance cost: By keeping replacement parts on-site you can keep maintenance costs down, with the simple design this can be done in-house

- Low personnel cost: Based on the powerful ecosystem and the number of users of Raspberry Pi, many users can quickly understand and get started on the technology

Available

- The Edge Series will remain in stable supply, relying on the strong manufacturing and logistics systems of Seeed Studio in Shenzhen, China. As long as you have needs, EUCA Technologies can provide you with all corresponding services and products

Reliable

- Industrial-grade protection is there. The series also has ESD protection and EMI shielding, as well as the isolated IO

- The RoHS/CE/FCC/UKCA/TELEC certifications and a two-year warranty are also provided